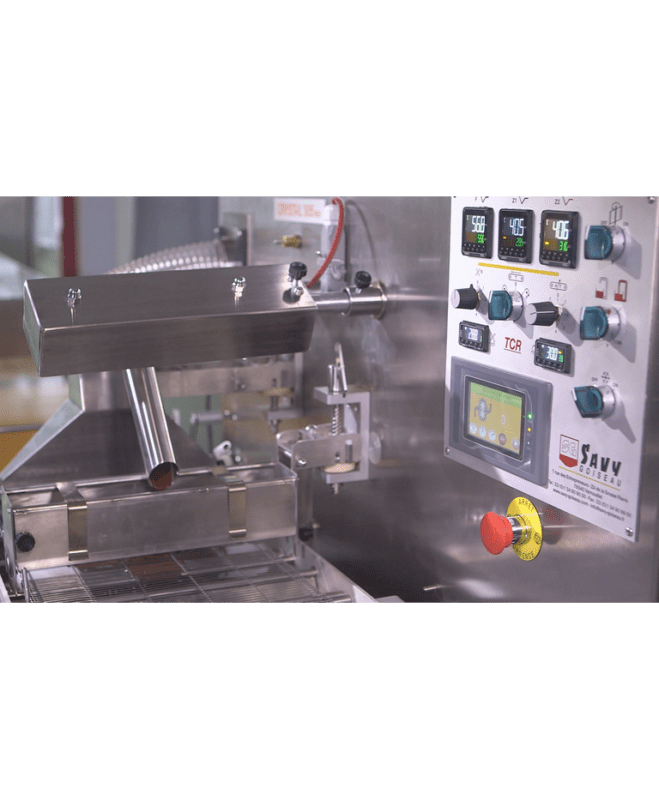

All SAVY GOISEAU tempering and coating machines are continuously tempered in 3 phases, the coating systematically passes through the 3 crystallisation temperatures (Melting 45/55°, descending to 27° for the creation of crystals, rising to the working temperature 30°), like a manual tempering cycle that avoids any thickening, after a few hours of work.

CRYSTAL TEMPERING – COATING MACHINES

THE NEW-GENERATION CRYSTAL!

Extended work area: Enlarged chassis for greater ergonomics

Recessed heated fan: Discreet and efficient

XXL hood: Wide opening and perfect temperature

Optimized air distribution: Uniform heating maintained

Integrated LED neon lights: For a touch of elegance

CRYSTAL coating machines are equipped with the exclusive TCR continuous tempering process.

The chocolate is continuously reheated and de-crystallized before a new curve is applied. which means you can work for hours on end, with a smooth, even coating.

In just 20 minutes, CRYSTALs are ready for continuous operation.

CONVEYORS: lg 800 mm exit or CHOCOPLAK

Option(s): – Heated vibrating table – Voltage: 230 v single-phase 50 / 60 Hz

– TRANSMOULERS – Pneumatic dosing head – Truffle kit

Tank capacity: 30 kg

Width of belt: 180 mm

400 V three-phase / 4 kW

Dimensions: l67 x L85 x h147 cm

Tempered chocolate/h: 120 kg/h

Coated products/day: 120 kg/day

THE NEW-GENERATION CRYSTAL!

Extended work area: Enlarged chassis for greater ergonomics

Recessed heated fan: Discreet and efficient

XXL hood: Wide opening and perfect temperature

Optimized air distribution: Uniform heating maintained

Integrated LED neon lights: For a touch of elegance

CRYSTAL coating machines are equipped with the exclusive TCR continuous tempering process.

The chocolate is continuously reheated and de-crystallized before a new curve is applied. which means you can work for hours on end, with a smooth, even coating.

CONVEYORS: lg 1200 mm exit or CHOCOPLAK

Option(s): – Heated vibrating table – Voltage: 230 v single-phase 50 / 60 Hz

– TRANSMOULERS – Pneumatic dosing head – Truffle kit

Tank capacity: 35 kg

Width of belt: 220 mm

220 V single-phase / 4 kW

Dimensions: l67 x L85 x h147 cm

Tempered chocolate/h: 140 kg/h

Coated products/d: 140 kg/d

CRYSTAL coating machines are equipped with the exclusive TCR continuous tempering process.

The chocolate is continuously reheated and de-crystallized before a new curve is applied. which means you can work for hours on end, with a smooth, even coating.

In just 20 minutes, CRYSTALs are ready for continuous operation.

TRANSPORTERS: 1500 to 3000 mm outlet or outlet on COLD TUNNEL

Option(s): – Heated vibrating table – Voltage: 230 v single-phase 50 / 60 Hz

– TRANSMOULERS – Pneumatic dosing head – Truffle kit.

Tank capacity: 60 kg

Width of belt: 300 mm or 400 mm

400 V three-phase / 7 kW

Dimensions: l87 x L112 x h152 cm

Tempered chocolate/h: 275 kg/h

Coated products/day: 200 to 300 kg/day