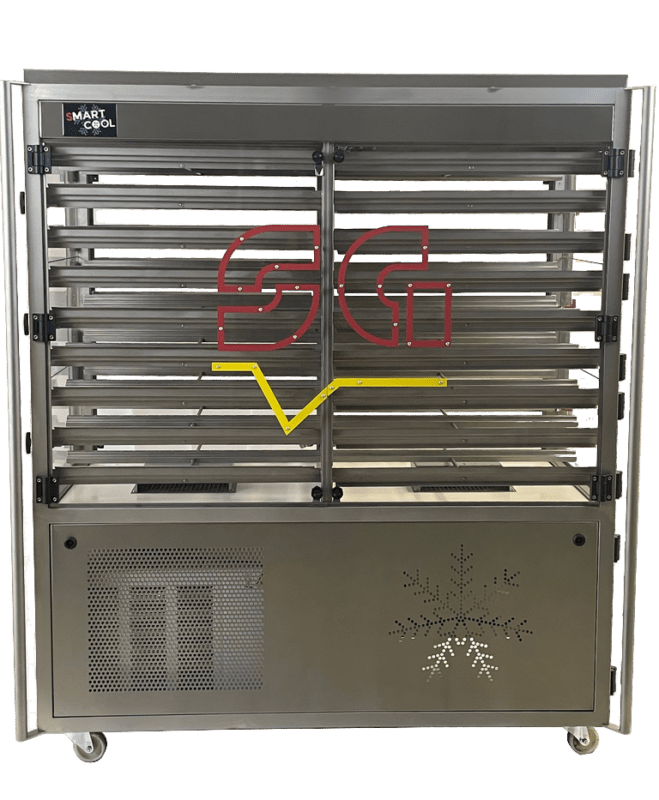

COOLING CABINET

SMARTCOOL is a practical and economical alternative to conventional cooling tunnels

- 9 storage levels

- Cooling with chiller and forced-air system

- Integrated dehumidification

- Mobile and space-saving

- Removable rails for cleaning

With self-contained refrigeration unit and 3 internal ventilation units for forced circulation of cold air over the products.

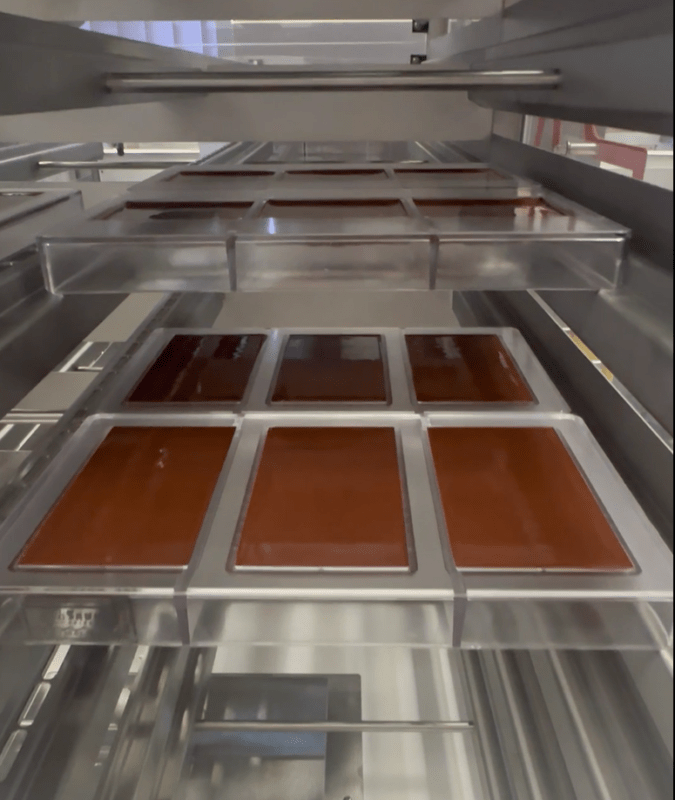

CAPACITIES :

16 x 9 levels of moulds 175 x 275 mm

20 x 9 levels of moulds 135 x 275 mm

4 x 8 plate levels 600 x 400 mm

4 x 2 large parts max. 300 x 240 x h400 mm

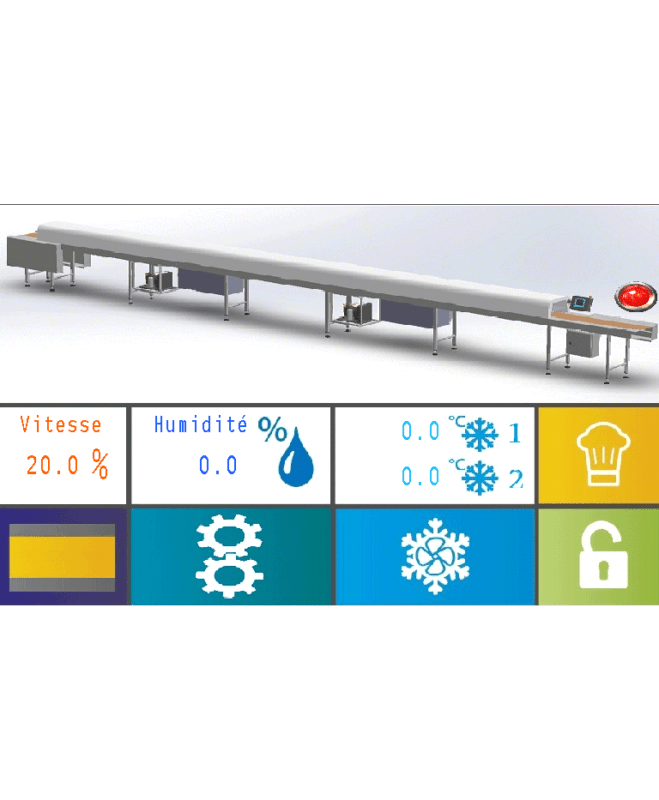

COOLING TUNNEL TRANSPLEX

The cooling tunnels « TRANSPLEX » have been specially developed at the request of chocolate makers who don’t have the space to fit a standard tunnel.

POSSIBLE LENGTHS :

4 m – 6 m – 8 m or +

4 m – 6 m – 8 m or +

WIDTH : 180, 220 or 300 mm

FEATURES :

DOWNLOAD THE DOCUMENTATION

– Stainless steel frame and conveyor

– Altuglass cooling boxes

– Variable-speed geared motor

COOLING TUNNELS CTU

Cooling tunnel with radiation with air circulating in a box above the products, which are cooled by radiation (air cooling can also be performed directly on the products).

Remove the chocolates by running over a second belt.

Cooling tunnel equipped with automatic belt guidance and air compressor.

POSSIBLE LENGTHS :

6 m – 8 m or +

6 m – 8 m or +

WIDTH : 220 or 300 mm